Bullion Canyon

Map Explore

Photos

Chart (Mouse wheel zooms in)

Story

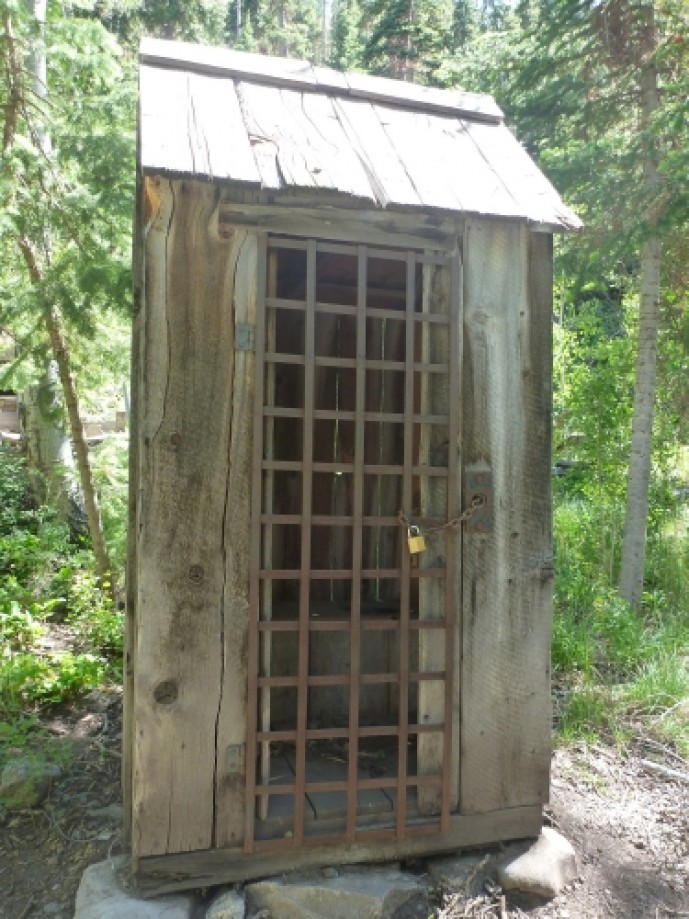

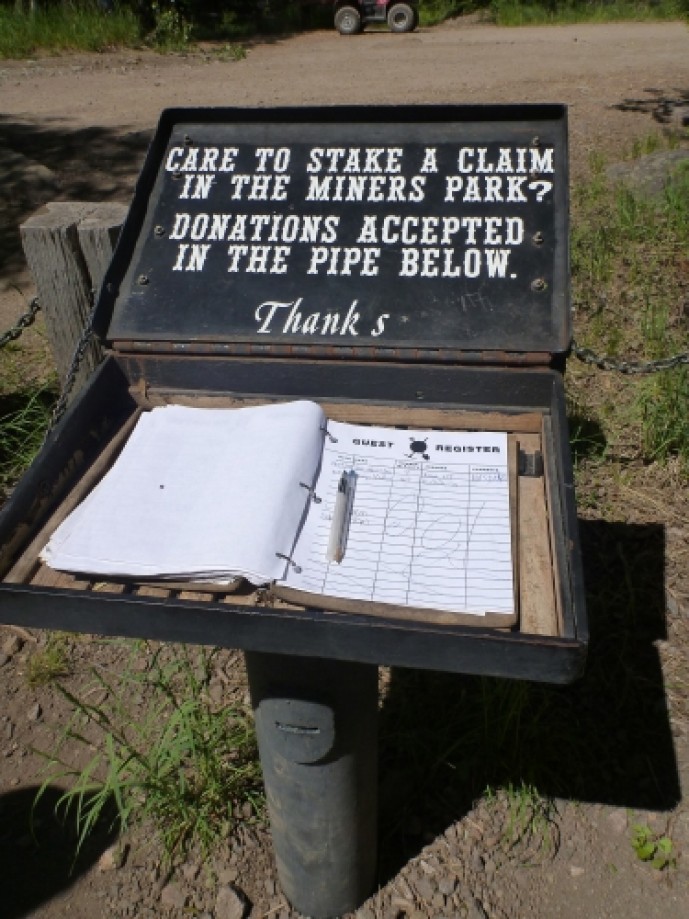

Canyon of Gold Driving TourCross the veil of time and discover the secrets of a canyon riddled with gold and the saga of men who sought her riches.Since the earliest days of human civilization, gold has enticed the souls of most mortal men.Gold! Gold! Gold! Gold! Bright and yellow, hard and cold Molten, graven, hammered rolled, Heavy to get and light to hold.(Thomas Hood, 1799-1845)The mouth of Utah's "Canyon of Gold" stretches before you. From at least 1865, flecks of gold in the creek and veins of gold inside her walls have drawn the hopeful to this canyon by the thousands.For the next 1-2 hours, this brochure will introduce you to the life and times of the miners of Bullion Canyon. Numbers in this brochure correspond to numbered posts found along the next 2.5 miles of this road. The road is rough in spots but is passable by most two-wheel drive vehicles.HELP PRESERVE OUR HERITAGE, DO NOT COLLECT ARTIFACTS OR DEFACE BUILDINGS.At this point, set your odometer to "0". Stop 1 is 0.6 miles past the trailhead.STOP 1 – Toll RoadSuccessful mining companies required transportation systems that allowed supplies, industrial equipment and building materials to be brought in while providing access for its workers and routes to remove gold, silver and lead. Roads were the life-lines to Virginia, Bullion and Webster cities, the three earliest communities of the canyon.Around 1869, D. C. Tate, a man named McCorkinlin and others built the first road into Bullion with $7,000 of their profits from the sale of the Morning Star Mine. A toll station was set up either at the mouth of Bullion Canyon or near the Marysvale Town spring (Stop 2). The road accessed the workings in the canyon including the Golden Curry Lode which had been in operation since 1868. To the dismay of the toll road operators, the local miners built a second road that was more direct and level than the pay road that climbed a steep ridge.The second road closely follows the road we drive today while the remnants of the toll road are visible on the north side of the modem road. Climb the stairs, stand on the platform, and look right and left. Although overgrown and littered with rocks, the toll road is still clearly visible.Without the heavy earth-moving equipment we take for granted today, road building during the 19th century was a slow, tedious and back-wrenching job.Stop 2 is 0.85 miles past the trailhead.STOP 2 – Mill CorralIn the late 1800's, the flat open area on the right side of the road (north) was occupied by corrals that probably stabled a small number of mules belonging to the Dalton Mill. Located about a mile up the road, the mill used mules to pull ore cars from mines still further up the canyon. Although the sleepers and rails have long since been removed, the bed of this ore car railroad can still be found along the north facing slopes of the canyon (Stop 7).Life in the gold mines of Bullion Canyon was tough for man and beast alike. Mules were worked long and hard but they did enjoy corrals open to the sky and fresh spring. In the California gold country, many mules spent their entire lives underground in mines which were indescribably dark, cold and wet. In the early 1900's, mules were replaced with "motors" (locomotives) powered by batteries or Model T gasoline engines.Because mules played such an important part in a successful mining operation, they were generally well-cared for. Over the mountain in the Kimberly Gold District, a well-liked mule was accidentally killed while underground. Distraught, the mule skinner refused to allow anyone to cut up the body of the animal which would have eased her removal from the mine.Stop 3 is 1.5 miles past the trailheadSTOP 3 – Witt Tate MineThe log buildings on both sides of the road were built by a prospector named Witt Tate sometime around 1920. Tate constructed the cabin and out-buildings to support his mining operation in the rocky ledges on the north side of the canyon.Witt sold the mine several times and in 1948, he sold the property to the Bullion Monarch. When the prospects failed to provide the new owners with enough capital to operate the mine, Tate foreclosed. This seems to be a pattern and many people now believe that Bullion Canyon produced more profits through speculation and the sale of worthless stocks than it did by the recovery of gold.What had led the owners of the Bullion Monarch to suspect the presence of high grade ores was Tate's discovery of deposits of lead. Gold is almost always associated with lead and silver and this alloy or combination of metals is always found with quartz. Millions of years ago, hot volcanic magma and mineralized fluids pushed up through the layers of the earth. Pockets of gold, lead and silver were left behind with quartz in the sandstone of Bullion Canyon.Witt Tate has been described as a successful miner.Stop 4 is 1.75 miles past the trailheadSTOP 4 – Dalton Mill and BoardinghouseThe clearing on the right side of the road (north) is where the main boardinghouse stood. Little remains of the log building except for a few scattered artifacts. The clientele of the boardinghouse were mostly single men who sought employment in the gold fields. Around 1920, the cost of staying in an accommodation like this could have been as high as $1.05 a day, with meals priced from 50¢ to $1.00. With wages ranging between $2.00 and $4.00 a day for laborers, muckers (shovelers), timbermen, carmen, and blacksmiths, most only made enough to provide the bare essentials.On the opposite side of the road, to the south and across the creek, are the remains of the Dalton Mill, erected sometime around 1892. The only remains of the mill are concrete foundations, a large flat pile of tan-colored tailings and rusted equipment which can be seen through the trees. When in operation, the mill received ore from large, 3 ton cars pulled on rails by mules which entered the top of the building about 250 feet up the slope. In the winter ore was brought to the mill on bull hides. Fed by gravity, ore moved downhill where it was mechanically crushed and pulverized along the way. At the bottom of the plant, gold ore was concentrated and shipped to Great Britain and later to Salt Lake City, where a smelter would create bars of pure gold bullion. Mines using the mill included The Wedge, Bully Boy, and Dalton.Stop 5 is 1.8 miles past the trailheadSTOP 5 – ArrastraFrom the traffic turnout, a narrow trail leads down the bank towards the stream. On the very edge of the creek and partially in the water is a large block of stone about 10 feet long. A circular depression 34 inches in diameter has been cut into the top of the stone.According to local lore, the first American miners to enter Bullion Canyon in the 1860's found rotted sacks of gold ore across the creek from this boulder. Perhaps earlier miners had reduced highgrade ore on this device which is called an arrastra.Arrastras were first introduced into the New World by the Spanish in the 1500's. To use a typical arrastra, ore was broken into walnut sized chunks with a sledge hammer and placed into the circular milling area. Three drag stones, chained to a post in the center of the milling area, were rotated by hand or mule. The drag stones crushed the ore into a fine powder and water was added until a thick slurry was produced.Mercury (quicksilver) was then introduced to the mixture which removed and amalgamated any gold found in the ore.Does the presence of this arrastra tell us that Spanish prospectors were in this canyon mining gold two or three hundred years ago? The answer is neither a simple yes or no because archaeologists have no way to "date" the arrastra.If we turn to written history for a clue, we are told that the Spanish were insatiable in their quest for riches. During the 1600's and 1700's, this appetite had driven them to explore most of what was to become the southern half of the United States.Because they had established a nearby stronghold in New Mexico (1598), it is possible that there were prospectors in Utah and maybe even in Bullion Canyon long before the first "official" expedition by the Spanish in 1776.Stop 6 is 2.15 miles past the trailheadSTOP 6 – Bullion CityAccording to Piute County Court documents, Bullion City may have been initially established at the mouth of Bullion Canyon near the Forest Service boundary. At some point, Bullion City was moved up the canyon. This move may have coincided with the reorganization of the Ohio Mining District in 1872. At this stop, you can look across the bridge and creek to the site of the relocated camp. During its heyday, the camp had 40 to 50 buildings, numerous tents and even dugouts. The 1880 census shows the population of the town as 1,651 souls, but 10 years later this figure had declined to 259. In 1922, when the Bully Boy Mill (Stop 8) was built, what was left of Bullion City became a company town with a population in the hundreds.Life in gold camps like Bullion City was hard. Health conditions were poor and often there was no medicine. Lodgings were primitive, most miners lived in tents or crude shelters with walls of canvas, hides or rough-hewn planks. Mining for gold required hard and monotonous labor. It was frequently necessary to work long hours while knee-deep in mud or icy water. Mine laborers generally worked 10 hour shifts, 6 days a week with Sundays off.Mining camps could also be dangerous places. Consider this account from a nearby mining camp by Merrill Utley in The Ghosts of Gold Mountain (1992):Two miners by the name of R. J. Gibson and J. Jacobs had been imbibing rather freely of the flowing bowl and got into a dispute over a gold claim ... They mutually agreed to retire to the street and settle their differences ... As they got into the street, they began pumping away at each other (with pistols) only a few feet apart. They missed!Fire was another danger and could easily devastate a town made of wood and canvas. It is said that a fire storm raged up the dirt road by the bridge on the right side of the creek (north) destroying a number of shacks and cabins. Look across the bridge and up to the south slopes of the canyon. As you drive up the road beneath these slopes, look for islands of aspen surrounded by spruce and fir trees. The aspen trees, recognized by their light green leaves in summer, are what grew back after a 1923 fire that started at a mine.Stop 7 is 2.2 miles past the trailhead.STOP 7 – Bullion City MeetinghouseIn front of you on the right side of the road (north) are the charred remains of a log cabin that served as Bullion City's meetinghouse.In the spring of 1994, the building was found to have burned to the ground. Evidence found in the ashes suggest that the burning of the cabin was person-caused either by intention or carelessness.PLEASE BE CAREFUL WITH FIRE; THE CONSEQUENCES CAN BE DEVASTATING.Turn to your left and look across the road. Several stone walls can be seen extending into the trees. These foundations are said to have supported an ore bin belonging to the Deseret Mine. From the walls, continue to turn to your left until you are facing slightly downhill. Look closely and in the grass just above the road, you will see a graded surface that was the bed for the 3 ton ore cars pulled by mules on track. It carried gold ore from the mines in this area to the Dalton Mill. The sleepers and rails are gone, but the grade can be followed to the millsite (stop 4).One of the cars that ran along this grade is on display at the Miners' Park (stop 9).Stop 8 is 2.25 miles past the trailhead.STOP 8 – Bully Boy MillOne of the most impressive reminders of the vitality and industry that once thrived in Bullion City is the Bully Boy Mill. Constructed in 1922, the mill received ore from the Bully Boy adits and The Wedge, Dalton, Great Western, Deseret, Cascade, Shamrock and Morning Star mines. The ruins of the mill measure over 238 feet long and 45 feet wide.The mill was a technological wonder for its time. Ore came to the top of the mill where it was dumped to start the mill circuit.As the ore moved downhill through the mill, it was mechanically ground into sand by crushers and stamps. Water was added to the crushed ore and the slurry mixture was moved to the "concentrators" where vibrating machines separated gold bearing ore from worthless rock scrap. The final step in milling ore involved passing the concentrated slurry mixture over large copper plates coated with mercury. Mercury was used because it attracts gold like a magnet attracts iron.In 1938, the mill closed because the cost of producing an ounce of gold exceeded the market value of gold which had been set by the government at $35 an ounce. Now deregulated, gold has recently approached $1,000 an ounce.Today the Bully Boy Mill is privately owned. Please respect private property.Do not enter the mill. IT IS UNSAFE!Stop 9 is 2.5 miles past the trailhead.STOP 9 – Miners’ Park Historical TrailThe Miners' Park, built by Forest Service volunteers, was the inspiration of Rell Fredericks, a local miner who has since passed on to higher prospects. His trail begins in front of the wooden mine car and continues to your right where it climbs into the trees. For 1/4 mile, the trail will take you to 16 displays of mining equipment, reconstructed workings and a refurbished cabin.When you have completed the walk around the Miners' Park, you might want to picnic in the area across the road. All 3 of the units have tables and fire rings. Please pack out all that you bring in.If you are in the mood for a scenic walk, a 2 mile round-trip trail begins at the bridge below the Bully Boy Mill. The trail will take you on the north side of the creek to an overlook above the Bullion Canyon water falls. These 60 foot falls are especially spectacular in the early summer when runoff swells the volume of the creek.For those who enjoy touring by auto, tum right onto Forest Road 126 just below the Bully Boy Mill. This 10 mile journey will take you near the 11,500' summit of Mt. Brigham and down through Cottonwood Canyon to U.S. Highway 89 just south of Marysvale. Be assured, the scenery is breathtaking. The road to Cottonwood Canyon is generally free of snow from mid-July to mid-November. The road tends to be rough in spots and higher clearance vehicles are recommended.PLEASE LEAVE THE BROCHURE IN THE TRAILBOX OR PAY $1.00 TO TAKE IT HOME.Ho for Bullion Canyon!Paint your wagon and come along!When American miners first traced placer gold up a seemingly untouched creek in Bullion Canyon, they were surprised to discover a crude ore crushing device – called an arrastra – and piles of ore. Who could have left this early artifact of mining? Perhaps gold hungry Conquistadores, riding north out of New Spain in the 1700s, had been the first to discover the riches of the canyon.To the good fortune of later miners, the Spanish seem to have left most of the gold-bearing veins in the canyon untapped. By 1868, the Ohio Mining District was established in Bullion Canyon and boasted three camps – Weber City, Virginia City, and Bullion City. The population of Bullion City is recorded as 1,651 in 1880.One of the more spectacular producers in the canyon was the Dalton Mine. Records show that $390,000 was mined from the first 100 feet of workings and that the Sylvester-Soderberg Stamp Mill was soon built to process the Dalton’s ore. Tailings and foundations from this operation still can be seen on the south side of the creek about a mile downstream from this spot.By the 1930s, the assay value of Bullion Canyon’s ore had dropped below mill grade. At this price, it was uneconomical to recover gold from the ore. The Bully Boy Mine and Mill, just east of this spot, hung on until 1938. Then, everyone was gone. But are they? It is said that on still, moonless nights a lone pick can be heard in the distance as if some ancient prospector is still searching for a new lode.Experience the life and times of the Bullion Canyon miners through the tools of their trade. Please follow the ¼ mile trail which starts on your right.Carving Roads into the WildernessWith the discovery of gold in the 1860s, roads had to be built to the diggings in Bullion Canyon. This implement is an early road grader called a "Fresno." It was pulled by a team of horses and was operated by two people. Using the handles at the rear of the grader, the operators would tilt it up at a scraping angle to the road.Water for the MillsPressurized water was used by the stamp mills in the canyon to wash and separate gold ore from dirt and debris. Originally, a 24" wooden pipe like this smaller pipe carried water from Bullion Falls above you to the Bully Boy Mill just below you. Note the large iron hooks on either side of the pipe that anchored the original pipe to the ground.Power from WaterIn the mines and mills of the canyon, piped water was converted to steam in boilers like the one before you. Steam was used to power pistons which ran the equipment necessary to ventilate mines and move, crush, separate and mill gold ore. This boiler, weighing more than 4 tons, was pulled by a team of 4 to 6 horses.Moving the OreOn your right is a stone boat. Pulled by a team of horses, boats hauled hundreds of pounds of gold ore over bone-jarring trails. Stone boads were used extensively in Bullion Canyon before the completion of the area's road system.On your left is an early car (ca. 1860s) which was used to truck ore from the mines. Built to run on 18 gauge track, the axles of this car have bee carved from cottonwood logs. Note the hand-wrought square nails used to build this car.This Skip Can Dump!This tupe of ore car is called a skip. It runs in a mine shaft on a track inclined upward 30 to 60 degrees. In the early days, a horse or a hoistman winched the car up the shaft.Norice that the back wheels or "truck" are set wider than the front wheels. At the top of the shaft, the truck goes up a separate, elevated track. The elevated track tilts the back of the skip and causes it to dump its ore. This skip was used around 1950.The DiggingsPicture yourself inside a very long and dark mine "tunnel" called an adit. For 12 to 14 hours a dary you would swing a sledge hammer or a pick against solid rock. If you couldn't afford a mule or horse, you loaded your cars with hundreds of pounds of ore and then pushed them by hand to the entrance of the adit. You then transferred the ore, again by hand, to an awaiting wagor or stone boat for the trip to the mill. Mining made many a man old before his time.Mining was also dangerous work. If a miner's adit had been shord up with wood and the wood eventually decayed, the rotting process used up large quantities of oxygen. Unfortunately, the oxygen in the adit was replaced with an unbreathable gas called carbon dioxide. Another danger wrose if a miner had cut through deposits of uranium in his search for gold. Radon gas, emitted from uranium, would collect in shafts often at dangerous levels. Years later, many miners would develop lung cancer.Mines continue to be hazardous places and should not be entered under any circumstance.Taming the RockThese drills were used to create pockets for sticks of dynamite which would blast tunnels through solid rock. All but two of the drills were used by hand and would have been hit repeatedly with a heavy sledge hammer. The large drill sticking out of the rock is a later type of drill (ca. 1910) powered by compressed air.Blast it to Smithereens!Adits are rarely "dug" but are frequently created with explosives. Explosions can't be set haphazardly; they're carefully channeled into a rockface by placing dynamite in drilled blast holes.This equipment seved as both mount and water supply for an air-powered drill. The bar supported the drill while the tank constantly bathed the drill and hole with water. Holes up to 400 feet deep could be drilled with this apparatus.New Mining TechnologyBy the turn-of-the-century, new technology made life easier and more efficient for the miner. Like the compressed air drill back at the adit, ore cars were now pulled by air-powered locomotives. A work car called a mucker even loaded ore into trailing cars with a large motorized scoop. In front of you are a mucker and a car used in the Deer Trail Mine from 1900 to 1936. They were capable of loading and carrying over a ton of ore per trip.Sharp Tools for Light WorkA self-contained hardware stone, called a "forge", sits before you! Especially in the older mines, miners were always at their forges sharpening and tempering red hot drill bits and hand tools. Because hardware stores were many miles away, the miner's forge was also used to build items such as hinges, pintels and nails and to fashion horse and mule shoes.Dalton CabinWas this cabin, called the Dalton Cabin by local folks, really built by the famous Dalton Gang? Are those bullet holes around the east-facing windows? What if we told you a Piute County Sherrif's posse made those holes in 1870 then they trapped the gang inside? Would you believe it if we said that a nine day siege by the posse killed four of the outlaws and that the surviving gang members were forced to eat Ned Dalton to stay alive?This story would make a great campfire tale but no such colorful history exists for this simple cabin!It was built by a miner in the 1920s on his claim about four miles above us at 10,500' elevation near Mt. Brigham's summit.It is very typical of mining cabins in this area. Ownership of this cabin was transferred to Myron Chellis "Chell" Dalton of Marysvale who bought the claim.The Dalton family lived in the cabin from June through November of each year while they mined for gold. Theone Dalton, son of Chell, fondly remembers those cool summer days and his mother's home cooking.In those days, most of hte family's meat came from the forest. On any given day, the meat in the stew pot could range from snowshoe rabbit to pine hen to venison.How does thsi cabin compare to your home? Could you be comfortable here for four to five months each year?Mine Cherries?To load a whole train in a narrow space early 20th century miners used a "Cherry Picker" like this one. These contraptions would lift empty cars in the air and swing them into place behind a mucker working the rockface. When a car was filled, it was scooted backwards and another empty car was swung into place. Locomotives, also called motors, horses and trammers, pulled the train full of gold ore to the mine entrance where awaiting transportation took the ore to the mill.Rainbows Aren't Always GoldenMining in Bullion Canyon was a back-breaking job whose success or failure rested within the fickle heart of Chance. Hardships were many, stakes were hard to get, living conditions were sub-standard and sometimes a vein just played out. In fact, more men were made poor by mining than rich. In front of you is a rectangular depression - the beginnings of a adit abandoned in an undetermined year for unknown reasons.A Hardrock PeriscopeSometimes the only difference between a miner who made money and one who went broke was an ability to successfully navigate a vein of ore as it snaked through a mountain. Veins of gold can be followed by continually testing for the presence and percentage of gold in mined ore.This piece of equipment is a steam-powered ore crusher used to prepare ore samples for testing. Ore was fed into the hopper on the left side of the machine and crushed on the right.Mining Has Been Around For A Very Long TimeMining has bee taking place here in Bullion Canyon for over 300 years. Mining has always been very important to the human race. Can you imagine your world without the products of mining? We would have no cars, trucks or trains (iron), airplanes (aluminum), satellites (gold), medicines and vitamins (lithium, magnesium), critical seasonings (salt) and nothing to conduct electricity (copper) or even generate it (coal, uranium) in waterless, windless or cloudy environments.Create a Future for Our PastWe hope you have gained an insight into early mining techniques and the role of mining in the history of Bullion Canyon. But remember - the sights, sounds, and smells of this canyon's gold camps are gone forever. However, you can help to create a future for the mine bulidings and artifacts that still cling to life all around you. Please report any diggins, collecting or defacing of these sites to the Piute County Sheriff.

This trip is from:

http://dyeclan.com/outdooractivities/funplaces/bullioncanyon/Other trips at: http://dyeclan.com/outdooractivities/

This trip is from:

http://dyeclan.com/outdooractivities/funplaces/bullioncanyon/Other trips at: http://dyeclan.com/outdooractivities/